What is closed cooling system ?

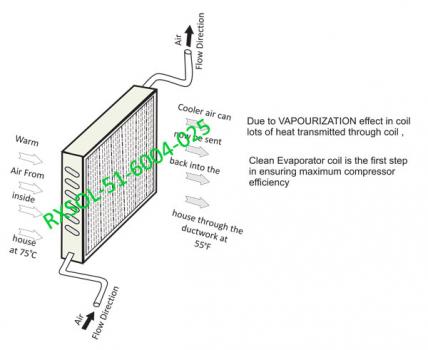

The full closed cooling system is designed to circulate cooling water through the block and exhaust manifold. water is circulated through water pump to heat exchanger tank and be pumped through many small tubes where it will exchange heat from the water of the circulating system. Then water exits the heat exchanger to go directly into the risers and then exit the boat. The exhaust manifold and riser will be blocked off, so no water will transfer between them. As for the circulating water in the closed cooling system, cool water will enter the engine through the circulating pump and circulate through the engine. The water will heat up in the engine and the warm water will exit at the water outlet on top of the manifold and head to the manifolds. After circulating through the manifolds, the hot water will head to the heat exchanger to exchange the heat it's carrying with the raw water. After the exchange the cool circulating water exits the heat exchanger and returns to circulating pump to begin another loop.

How to Protect internal combustion engines, compressors, chiller system and DG sets from Corrosion?

ROCCOR NB Corrosion Inhibitor is a unique formulation with highly concentrated liquid cooling treatment compound, ferrous & Non ferrous corrosion inhibitors, antiscalants, dispersant and buffer solution of non carbonate.

ROCCOR NB is specialized such a way which can be use in high or low temperature closed cooling water systems for the prevention of corrosion and scale formation in internal combustion engines, compressors, chiller system and DG sets. Also Usefull to Protects all metals including cast iron, mild steels and copper. Recommended ppm levels are easily controlled by standered RXSOL test kit Nitrite / Chloride.

The stable protective microfilm prevents corrosion caused by electrolytic action and the alkaline nature of this product prevents acid attack.

The stability of the added polymers are very useful for water treatment processes. Such polymers with low molecular weights cannot only inhibit calcium, magnesium, and silica scale in cooling towers and boilers, but also help corrosion control by dispersing iron oxide.

FIELDS ::: --- Suitable for use in closed water cooling systems, ice melting systems and transformer cooling systems. The product may be used in all kinds of diesel & petrol engines, compressor or heating cooling water circuits.

Where Roccor NB can be used?

Prolongs the life of equipment by keeping it scale and corrosion free. Since RXSOL-40-4001-025 is alkaline, it will suppress acid corrosion, which would otherwise result in sever pittings. It improves cooling efficiency by maintaining clean heat transfer surfaces , from Radiators, DG - sets, Closed Cooling and chiller System.

FIELDS ::: --- Suitable for use in closed water cooling systems, ice melting systems and transformer cooling systems. The product may be used in all kinds of diesel & petrol engines, compressor or heating cooling water circuits.

( Used as a corrosion inhibitor for all ferrous and non-ferrous metals found in water systems )

DOSES and Using procedure of ROCCOR NB?

GENERAL RECOMMENDATION : ( The dosage chart may be used as a guide to adjust treatment to obtain the optimum level.)

Nitrite (as PPM NO2) 0 100-200 300-600 700-900 1100-1300

RXSOL-40-4001-025 / 1000L 8.0 7.3 7-8 5-7 1.5-3.5

NOTE ::: -- If nitrite level becomes 1440-2400 then doses should be ZERO.

The initial dosage for an untreated system is 8 liters of product per 1000 liters of water. Such a dose will bring nitrite levels over 1200 ppm. Maximum nitrite level is considered to be 2400 ppm. Frequent tests should be carried out in order to maintain pH values within the limit (8.3-10.0), while levels of chloride should be maximum 50 ppm.

Initial dosage for an untreated system is 9 litres of RXSOL-40-4001-025 / 1000 litres of untreated distilled water. This will bring the treatment up to the minimum level of 1000 ppm nitrite. For best result and prolonged engine life add RXSOL-40-4001-025 every 500 -6500 km. or 250 to 300 hours of running time or every 2 month interval. Specially designed for use in water systems of internal combustion equipment. pH should be maintained between 8.3 and 10 by the treatment.

RXSOL-40-4001-025 will react with sludge and in most cases, facilitate sludge gradual removal. On badly fouled systems with oil or scale, a prior degreasing by using DEGREASER HEAVY DUTY or descaling by using DEGREASER HEAVY DUTY, SCALE REMOVER LIQUID or SCALE REMOVER POWDER is highly recommended.

• Excellent corrosion inhibitor for cooling water

• Minimises metal oxide deposits

• Protects ferrous and non-ferrous metals

• Compatible with glycol-based antifreeze

• Reduces cleaning & maintenance costs

• Cost effective, easy to apply and use

ROCCOR NB Corrosion Scale Inhibitor Liquid specialized marine chemical product for Cooling Water treatment. ROCCOR NB Corrosion Scale Inhibitor Liquid supplier in Mumbai, Kandla Mundra, TURBHA MIDC NAVI Mumbai, Hazira SURAT, Visakhapatnam, Gangavaram, Chennai, Ennore, Kolkata, Haldia, Paradip, Kakinada, Fujairah, Ajman, Abudhabi, Sharjah, Dubai, UAE GULF, Ruwi Gala Barka, Muscat Oman, Canada, Nairobi Kenya Sudan, Yemen

.jpeg)